The temperature of marine bearings can usually be inferred from the external temperature of the bearing pedestal. However, it is more correct to directly measure the temperature of the bearing outer ring by using the oil hole. The bearing temperature rises gradually from the start of operation, and usually stabilizes after 1-2 hours. If the bearing is not installed properly, the temperature will rise sharply, and abnormal high temperature is found. The reasons include too much lubricant, too small bearing clearance, poor installation, excessive friction of sealing device, etc. In the case of high-speed rotation, the bearing structure and lubrication mode are also the reasons. The rotating sound of the bearing is checked with a stethoscope, and strong metal noise, abnormal noise, irregular sound and other indications are abnormal. The reasons include poor lubrication, poor accuracy of shaft or bearing seat, bearing damage, foreign matter intrusion, etc.

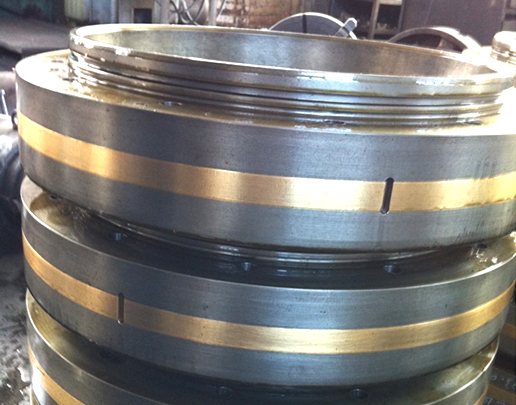

Marine rolling bearings are generally composed of four parts: outer ring, inner ring, rolling element and cage. Strictly speaking, they are composed of six parts: outer ring, inner ring, rolling element, cage, seal and lubricating oil. There are mainly outer ring, inner ring and rolling element, which can be defined as rolling bearing. According to the shape of rolling elements, rolling bearings are divided into ball bearings and rolling bearings.

Lubrication performance analysis of marine intermediate bearing in Dalian marine parts

1) Under some typical rotating speed conditions, the smaller oil film thickness of marine intermediate bearing is 11.20 μ m. The comprehensive roughness of the lubricated surface greater than 2 is 0.894 μ M value. At the same time, the smaller film thickness ratio is 13.42, which is much larger than 3. Therefore, the marine intermediate bearing is fully lubricated at various speeds, and the lubrication condition is good.

2) Because the marine intermediate bearing is in the state of full film fluid lubrication, the friction and friction generated by the marine intermediate bearing in operation are mainly caused by the viscous shear force of the lubricating oil.

3) The friction and friction power consumption of marine intermediate bearings are closely related to the lubricating oil inlet temperature and journal speed. With the increase of rotating speed, the friction, friction coefficient and friction power consumption of the intermediate bearing also increase. With the increase of lubricating oil temperature, the friction, friction coefficient and friction power consumption of the intermediate bearing decrease gradually.

Rolling bearings include ball bearings and rolling bearings. It is much easier to design rolling intermediate bearings than sliding intermediate bearings. As long as a reasonable bearing is selected from the bearing samples according to the shaft diameter, speed and load of the intermediate bearing to be designed, the shell of the bearing can be designed according to the selected bearing. In many applications where the load and speed are not too strict, the rolling bearings can be more suitable for the sealing structure filled with grease, and do not need grease and maintenance during the whole service life. Since there is no worn surface to repair, it is very convenient to replace the spare rolling bearing. At the same time, the friction coefficient of rolling bearing is much smaller than that of sliding bearing.

Generally speaking, the proper application of rolling bearings can achieve fatigue service life. However, in case of accidental initial damage, it cannot be applied again. Unlike the fatigue service life, this kind of initial damage is called common failure or safety accident. Most of them are caused by lack of consideration in installation, application and lubrication, dirty things invaded from the outside, or insufficient scientific research on shafts and bearings with seats. The damage of rolling bearings, such as the abrasion of the throw ring retaining edge of roller bearings, may be caused by insufficient lubricating fluid, inappropriate model, defective oil supply and drainage structure, invasion of dirt, bearing installation deviation or excessive tensile strain of the shaft. It may also be caused by various reasons above.