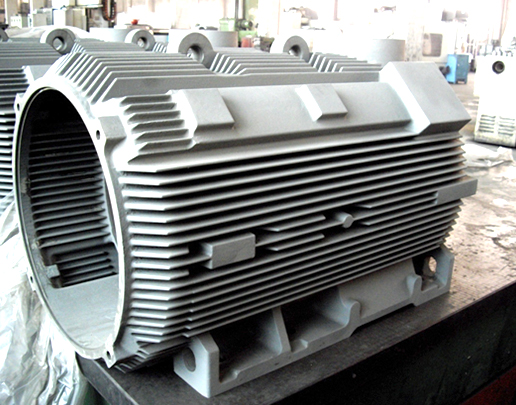

There are many types of processing for Dalian motor shells, which can be customized according to the actual usage location and product size of the customer's micro motor. They are not standard parts and can be used. Therefore, during the customization process, external materials must be selected according to our actual requirements to protect our motor. The quality of motor casing processing is often overlooked by customers. In their eyes, motor casing processing is only a subsidiary service, and they only focus on the quality of these important components of the motor.

Generally, after running the motor for 5000 hours, the lubricating grease should be filled or replaced. If the bearing temperature is too high or lubrication is found to be updated or modified during operation, the hydraulic press should immediately lubricate the grease. When disassembling and replacing lubricating grease, the old lubricating grease should be removed, and the bearings and bearing covers should be cleaned with gasoline from the car fuel tank, and then added to the inner and outer ring cavities of the bearings. Disassembly and replacement of winding resistors include primary and intermediate winding resistors, specifications, coil turns, and wiring. When data and information are lost, the processing plant should be specified to arbitrarily change the initial design scheme of the motor winding resistance, which is generally one or more malignant changes and cannot even be applied.

Precautions for Painting Construction of Dalian Motor Shell:

1. The construction method can choose automatic spraying mode, using an automatic spraying machine to seal it inside the tank. This construction method is more efficient, and transportation and storage are also more convenient.

2. The same object should use the same color and choose products from the same batch to avoid significant color differences.

3. Before construction, the spraying effect should be tested to see if the spraying is uniform and if there are any equipment malfunctions. Avoid situations where the spraying effect varies in depth and intensity.

4. When spraying, it is necessary to wear protective clothing, as harmful substances can be generated when the paint evaporates. If left unprotected, it can cause significant harm to workers.

The daily maintenance of the motor casing is crucial for reducing and avoiding motor malfunctions during operation. Regular inspections and timely troubleshooting of abnormal phenomena are necessary. After the accident occurred, conducting a serious accident analysis and taking countermeasures is an indispensable technical work to reduce the number of accidents and improve the efficiency of motor operation when repairing the stop platform. Water droplets, oil stains, dust, etc. cannot enter the interior of the motor. Regularly remove dust from the inside and outside of the motor. Please note that the load current does not exceed the rated current.

If the temperature of the motor casing rises too fast, it may be a common fault. The common faults of hot motor casings include: damaged rolling bearings (which can be distinguished by sound at low speeds), mild short circuit faults in electromagnetic coils (which can be distinguished by measuring the balance of three-phase current), and broken motor rotor bars. (At this time, there is also an imbalance in three-phase current, but the detailed condition of the motor casing requires unique instruments and equipment to accurately measure.) Sweeping the bore (the axis management center is offset, related to rolling bearings). External cause of hot motor casing: phase failure. Or a certain phase is loose, etc.