As an important component of the motor, the Dalian motor casing plays a crucial role in the performance and lifespan of the motor. With the continuous development and progress of motor technology, the design and manufacturing of motor housings are also constantly innovating and improving to adapt to different usage environments and requirements. The quality and craftsmanship level of the motor casing are directly related to the safety and stability of the motor, so manufacturers need to attach great importance to and carefully design and manufacture it.

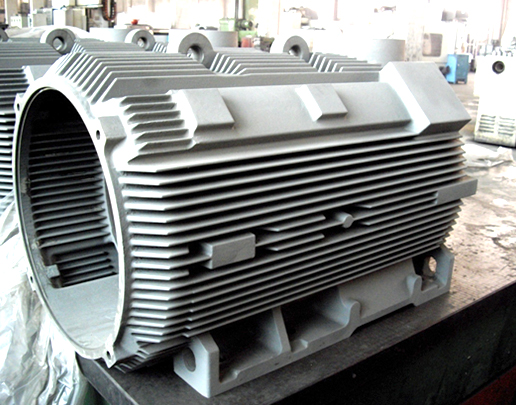

The motor generates heat during operation, and the motor housing usually has good heat dissipation performance, which can timely dissipate the heat generated inside the motor, prevent the motor from being damaged due to overheating, and ensure the performance and reliability of the motor. It can play a certain electromagnetic shielding role, reducing the impact of electromagnetic interference generated during motor operation on surrounding electronic devices, and also preventing external electromagnetic signals from interfering with the internal circuit of the motor.

How are the shapes and dimensions of the Dalian motor casing designed?

Consider the performance requirements of the motor

Power and torque: High power, high torque motors typically require larger stator and rotor sizes to accommodate more windings and stronger magnetic fields. Correspondingly, the size of the motor casing will also be larger to ensure sufficient space and strength.

Speed: High speed motors have higher requirements for the structural strength and heat dissipation performance of the motor housing. In order to reduce the influence of wind resistance and centrifugal force, the shape of the high-speed motor housing may be more compact and streamlined to improve the operational stability and efficiency of the motor.

Heat dissipation requirement: The motor generates heat during operation, and heat dissipation performance is an important factor affecting the performance and lifespan of the motor. Therefore, when designing the motor casing, it is necessary to design the heat dissipation structure and channels reasonably according to the heat dissipation requirements of the motor. For example, adding heat dissipation ribs, heat dissipation holes, or using heat dissipation fans to improve the heat dissipation efficiency of the motor casing.

Suitable motor type

DC motor: The structure of a DC motor is relatively simple, and its motor housing shape is usually cylindrical or square. For small DC motors, cylindrical motor housings are generally used for ease of manufacturing and installation; For large DC motors, a square motor housing may be used to improve space utilization and heat dissipation performance.

AC motors: There are many types of AC motors, such as asynchronous motors, synchronous motors, etc., and their motor housing shapes and sizes also have their own characteristics. The motor housing of asynchronous motors is usually cylindrical, and its size depends on the power and number of poles of the motor; The motor housing of a synchronous motor may be square or circular, and due to the complex structure of synchronous motors, the size and shape of the motor housing need to be optimized according to the specific motor design.

Follow installation requirements

Installation method: The installation methods of the motor mainly include horizontal installation, vertical installation, and wall mounted installation. Different installation methods have different requirements for the shape and size of the motor casing. For example, horizontally installed motor housings are usually cylindrical in shape and have mounting feet or flanges at the bottom to facilitate the fixation of the motor; The motor casing for vertical installation may be square or circular, with mounting holes or flanges on the top or sides to accommodate different installation requirements.

Installation space: The installation space of the motor is also an important factor in designing the shape and size of the motor casing. When designing the motor casing, it is necessary to fully consider the installation position and surrounding environment of the motor, ensuring that the shape and size of the motor casing can meet the requirements of the installation space.

Based on manufacturing process and cost

Manufacturing process: The manufacturing process of motor casing mainly includes casting, welding, and stamping. Different manufacturing processes have certain limitations on the shape and size of the motor casing. For example, the casting process can produce motor housings with complex shapes, but the dimensional accuracy is relatively low; The welding process can produce large and high-strength motor casings, but requires advanced welding techniques and equipment; Stamping technology is suitable for manufacturing motor housings with simple shapes and small sizes, and has high production efficiency and low cost.

Cost factor: The cost of the motor casing is also an important factor to consider during design. On the premise of meeting the performance and installation requirements of the motor, low-cost materials and manufacturing processes should be selected as much as possible to reduce the manufacturing cost of the motor. For example, for small motors, stamping technology can be used to manufacture the motor housing to reduce costs; For large motors, it may be necessary to use casting or welding processes to manufacture the motor housing to ensure its strength and performance.

The motor housing occupies an important position in the motor manufacturing process, and the manufacturing process includes various methods such as stamping, casting, injection molding, etc. For different types and specifications of motors, the manufacturing process of the motor casing will also vary, and the appropriate production method and process flow need to be selected according to the specific situation. The production of motor casings requires strict process control and quality inspection to ensure that the product quality meets the requirements.

Enclosed motor housing: This type of motor housing can completely enclose the internal components of the motor, effectively preventing external substances such as dust and moisture from entering the motor. It is suitable for harsh environments such as outdoor, mining, factories, etc. Open type motor housing: The structure of the open type motor housing is relatively simple, with good heat dissipation performance, but poor protection performance, and the internal components of the motor are easily affected by the external environment. Generally suitable for clean and dry environments, such as well ventilated indoor computer rooms.