Dalian marine components are an indispensable and important part of ships, and their performance and quality directly affect the safety and operational efficiency of ships. With the continuous advancement of technology and the continuous development of the market, marine components are developing towards intelligence, environmental protection, and new materials. In the future, with the further application of new materials, new processes, and intelligent technologies, marine components will usher in a broader development prospect.

The maintenance and upkeep of marine components are important steps in ensuring the safe operation of ships. Regular inspection and maintenance can promptly detect and handle wear, corrosion, and malfunctions of components, extend their service life, and reduce the maintenance costs of ships. Maintenance and upkeep work includes cleaning, lubrication, fastening, replacement, etc., which need to be arranged reasonably according to the usage of the components and the manufacturer's recommendations.

What are the quality and performance standards for marine components in Dalian?

international standard

International Maritime Organization (IMO) standards

IMO has formulated a series of conventions and regulations on ship safety, pollution prevention, and other aspects, such as the International Convention for the Safety of Life at Sea (SOLAS), the International Convention for the Prevention of Pollution from Ships (MARPOL), etc. These conventions set basic requirements for the safety and environmental protection of ship components. For example, SOLAS requires that life-saving equipment, firefighting equipment, and other components of ships must meet corresponding safety standards to ensure normal use in emergency situations and safeguard the lives of crew and passengers.

The International Convention on Load Lines specifies the structural strength and stability of ships, indirectly involving the strength and reliability requirements of ship components.

International Organization for Standardization (ISO) standards

ISO has released many standards related to marine components, such as ISO8846-2004 "Fire Test for Protective Enclosures of Ship Electrical Equipment", which specifies the fire test methods and requirements for protective enclosures of ship electrical equipment, ensuring the safety and reliability of electrical equipment in case of fire.

ISO 12215-5 "Small Boat Hull Structure Part 5: Materials, Dimensions, and Thickness to the Small Boat Body" specifies the materials, dimensions, and thickness to the small boat hull structure, providing a basis for the selection and design of components for small boats.

national standard

Chinese National Standard (GB)

GB/T 3030-2013 "Test Methods for Marine Diesel Engine Test Bench" specifies the test conditions, test items, test methods, and measurement and calculation methods of performance indicators for marine diesel engines during bench testing, ensuring that the performance and quality of marine diesel engines meet the requirements.

GB/T 1163-2014 "Marine flange bronze check valves" specifies the structural form, basic parameters, technical requirements, test methods, etc. of marine flange bronze check valves, ensuring the quality and performance of marine check valves and enabling them to work reliably in ship piping systems.

American National Standards Institute (ANSI)

ANSI/ABYC H-27 "Marine Sanitation Systems and Components" specifies the design, installation, and performance of ship sanitary systems and their components to ensure the normal operation of ship sanitary systems and prevent pollution.

ANSI/SAE J1708 "Marine Engine Exhaust Systems" specifies the design, materials, installation, and performance requirements for marine engine exhaust systems, ensuring that the exhaust system can effectively discharge exhaust gases while meeting safety and environmental requirements.

Industry standards

China Classification Society (CCS) specifications

CCS has developed a series of ship classification standards, such as the "Classification Standards for Steel Ships", which provide detailed requirements for the structure, equipment, systems, and other aspects of ships. For marine components, specifications specify their materials, manufacturing processes, inspection and testing methods, etc. Only components that meet the requirements of the specifications can be used for classified ships. For example, in terms of ship structure, there are strict requirements for the strength, toughness, welding performance, etc. of ship steel; For the mechanical and electrical equipment of ships, it is required to have good reliability, safety, and adaptability.

The "Classification Specification for Offshore Mobile Platforms" also specifies the requirements for components used in offshore mobile platforms. Considering the special working environment of offshore platforms, there are higher requirements for the corrosion resistance, fatigue resistance, and other performance of components.

American Bureau of Shipping (ABS) specifications

ABS's' Rules for Building and Classifying Steel Vessels' provide detailed guidance on the design, manufacturing, and inspection of marine components. For example, for marine boilers and pressure vessels, ABS specifications specify requirements for material selection, structural design, manufacturing processes, and non-destructive testing to ensure the safety and reliability of these components during ship operation.

The ABS Guide for the Certification of Marine Electrical Equipment provides guidance on the certification of marine electrical equipment, including generators, motors, distribution equipment, etc., requiring these devices to meet corresponding standards for electrical performance, safety performance, and environmental adaptability.

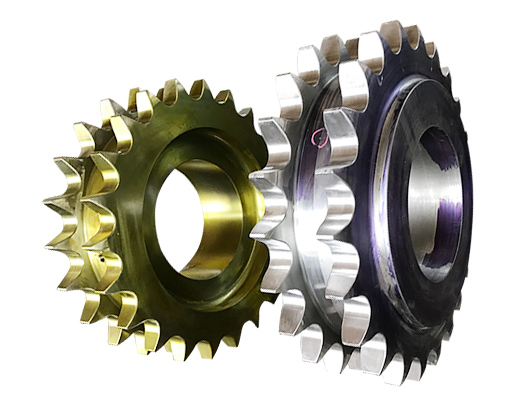

The material selection of marine components is crucial, usually requiring high strength, corrosion resistance, wear resistance and other characteristics. Common materials include steel: High strength steel is commonly used for ship structures and many mechanical components to ensure the strength and durability of the vessel. Aluminum alloy: widely used to reduce the weight of ships, especially in high-speed vessels and yachts. Composite materials, such as fiberglass and carbon fiber, are used to manufacture lightweight, high-strength components such as ship hulls and decks.

The manufacturing of marine components requires strict quality standards and process flow. Multiple processes such as material selection, processing, heat treatment, and surface treatment are required during the manufacturing process to ensure the strength, corrosion resistance, and service life of the components. At the same time, the selection of marine components also needs to be comprehensively considered based on the type, purpose, and navigation environment of the vessel. For example, ocean going vessels need to choose components with high corrosion resistance and reliability, while inland vessels can choose components with lower costs and easier maintenance.